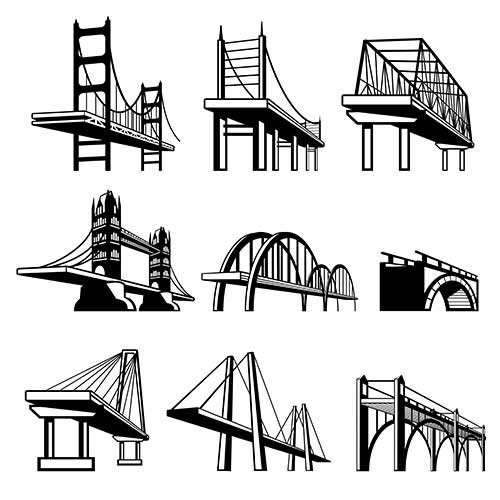

Bridge

Depending on the type of layout, we can offer design and build services.

The Design of a new bridge is approval by its intended purpose, its location, the expected loading on the structure and the available funding.

On every project, we aim for aesthetic, economical and most importantly constructible solutions that meet the requirement of our Client.

Key Features:

- Creative spirit

- Fabrication expertise to notify the design

- Expertness of economical detailing

- Early accuracy in cost projections

Steel bridges have been an essential part of infrastructure development for many years, providing safe and efficient transportation for people and goods. The design, fabrication, and installation of steel bridges require careful planning, attention to detail, and adherence to strict quality standards. In this article, we will explore the key aspects of the design, fabrication, and installation of steel bridges.

Design of Steel Bridges

The design of steel bridges typically involves the following steps:

- Site survey and analysis to determine the site conditions, including topography, soil conditions, and environmental factors.

- Preliminary design and feasibility study to determine the bridge’s required load capacity, span length, and overall dimensions.

- Detailed design to finalize the structural details, such as the beam size, column spacing, and foundation design.

- Structural analysis and testing to ensure the bridge’s safety and structural integrity under different load conditions.

Fabrication of Steel Bridges

- Cutting and shaping the steel members according to the design specifications using CNC machines or traditional fabrication methods.

- Welding or bolting the steel members together to form the bridge’s structural elements, including the beams, columns, and trusses.

- Quality control and inspection to ensure that the fabricated components meet the required specifications and quality standards.

- Surface treatment, such as painting or galvanizing, to protect the steel components from corrosion and weathering.

Installation of Steel Bridges

- Site preparation, including excavation, grading, and foundation construction.

- Assembly of the structural components on-site, including the beams, columns, and trusses.

- Lifting and positioning the bridge’s structural components into place using cranes or other lifting equipment.

- Bolting or welding the structural components together to form the completed bridge.

- Quality control and inspection to ensure that the installation meets the required specifications and quality standards.

In conclusion, the design, fabrication, and installation of steel bridges require careful planning, attention to detail, and adherence to strict quality standards. By following a well-defined process that incorporates the best practices in design, fabrication, and installation, steel bridges can provide safe and efficient transportation for many years.